Workplace Health and Safety Policy Statement

We are committed to providing a safe and healthy work environment for our employees, contractors, volunteers and visitors.

We are committed to providing a safe and healthy work environment for our employees, contractors, volunteers and visitors.

We have a proactive culture that ensures we:

- provide a proactive approach to risk management

- maintain compliance

- engage and consult with workers

- monitor WHS performance

- provide health and wellbeing support

- aim for continuous and sustained improvement.

All employees have an obligation to maintain a safe and healthy workplace, and to uphold all relevant policies and procedures.

Read our Workplace Health and Safety Policy Statement.

WHS legislation and your obligation

According to the Work Health and Safety Act 2011 (the WHS Act) and associated WHS regulations, codes of practice and Australian standards, contractors:

- have a duty under the WHS Act to provide a safe place and a safe system of work so as not to place at risk the contractor’s own workers as well as other workers and the general public at the workplace.

- must comply with all relevant enactments, associated WHS regulations, standards, codes of practices and TRC WHS policies and procedures that are applicable to a contract, or the performance of the services under the contract.

While at work, workers are required to take reasonable care for their own health and safety and that of others who may

be affected by their actions or omissions irrespective of what

workplace they are employed at.

Due diligence

The WHS Act imposes a specific duty on officers of corporations and unincorporated bodies, such as clubs and associations, to exercise due diligence to ensure that they meet their work health and safety obligations. The duty requires officers to be proactive in ensuring that the corporation, club or association complies with its duty.

What is due diligence?

In demonstrating due diligence, officers need to show that they have taken reasonable steps to:

- acquire and update their knowledge of health and safety matters

- understand the operations being carried out by the person conducting the business or undertaking in which they are employed, and the hazards and risks associated with the operations

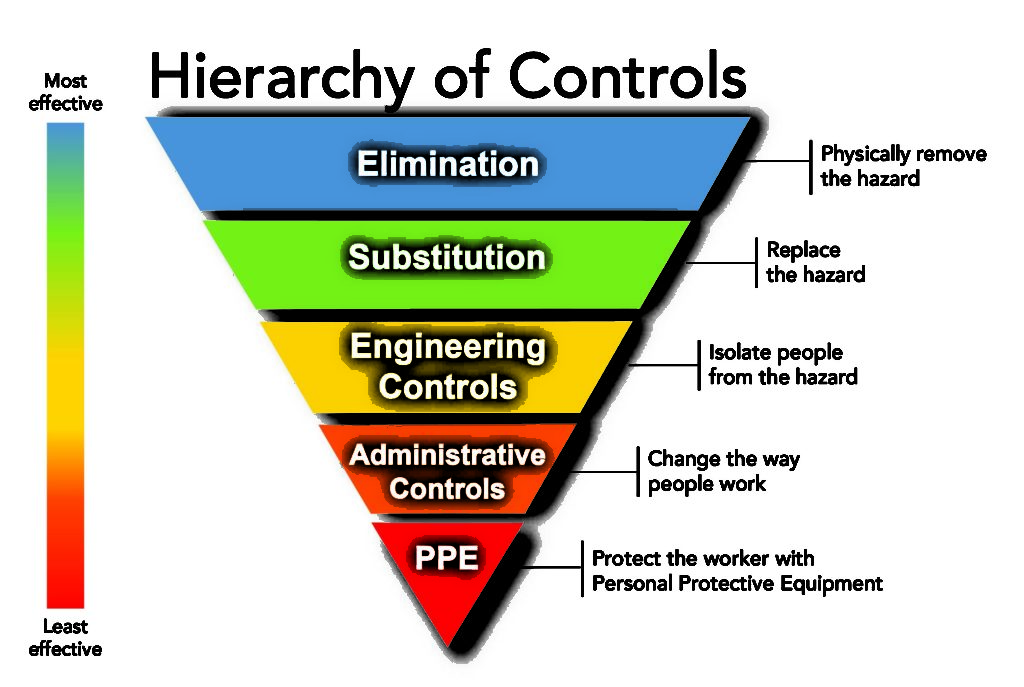

- ensure that the person conducting the business or undertaking (PCBU) has, and uses, appropriate resources and processes to eliminate or minimise health and safety risks arising from work being done

ensure that the PCBU has appropriate processes in place to receive and respond promptly to information regarding incidents, hazards and risks - ensure that the PCBU has, and uses, processes for complying with duties or obligations under the WHS Act.

TRC WHS Management System

The TRC WHS Management System consists of seven key elements.

Element 1 — Policy, commitment and management

Element 2 — Systems planning and development

Element 3 — Systems implementation

Element 4 — Control of specific work environment risks

Element 5 — Control of specific work equipment risks

Element 6 — Monitoring, reporting and evaluation

Element 7 — Review and continual improvement

Element 3 — Systems implementation has eight sections

3.1 — Consultation

3.2 — Emergency preparedness

3.3 — First aid management

3.4 — Infection control

3.5 — Training

3.6 — WHS induction

3.7 — Purchasing and suppliers

3.8 — Contractor controls

3.8.1 Contractor controls

Obligations

Under the WHS Act, duties are imposed on TRC to ensure its workers and contractors carry out their work in a safe manner.

Contractors also have duties under the WHS Act as a person conducting a business or undertaking (PCBU) and/or a person in control of the workplace. This means the contractor must also carry out their work in a safe manner without risk to themselves, their workers and all others.

Hazard identification

The contractor will be required to undertake a site hazard identification to systematically identify and assess hazards.

Hazardous work

Specific indication for hazardous work must be outlined e.g. hot work permit, hazardous chemicals, confined spaces permit, asbestos, excavation, trenching and height work.

Risk Assessment

The contractor must conduct risk assessments and relevant control strategies prior to commencement of work if risks are identified. For high risk activities a safe work method statement (SWMS) must be completed.

5.4 Consultation and participation of workers

The organisation shall establish, implement and maintain a process(es) for consultation and participation of workers at all applicable levels and functions.

7.4 Communication

7.4.1 General

The organisation shall establish, implement and maintain the process(es) needed for the internal and external communications relevant to the OH&S management system

6.1.2 Hazard identification and assessment of risks and opportunities

6.1.2.1 Hazard identification

The organisation shall establish, implement and maintain a process(es) for hazard identification that is ongoing and proactive. These include those with access to the workplace and their activities, including workers, contractors, visitors and other persons.

At All TRC Sites

Contractors must:

- sign in and out or obtain a visitors pass if engaged for consecutive days of work

- ensure to follow walkways

- ensure private vehicles do not to enter depots

- wear high-vis clothing at all depots

- have conducted a TRC general inductions

- follow TRC’s WHS policies and procedures.

If you are unsure on how to conduct a particular work task or process in a safe manner, just ask!

WHS Business Partner

WHS Business Partners are employed by TRC and their duties include advising TRC about the overall state of health and safety at workplaces and conducting audits and inspections.

Alcohol and Drugs

The use of alcohol and drugs in the workplace is not tolerated. Being unfit for work as a result of alcohol may result in disciplinary action. Use of any drugs, other than those prescribed by a medical practitioner or legally obtained over the counter medication, will not be tolerated in the workplace. All workers, including contractors, must neither be in possession, nor under the influence, of alcohol or drugs while on a TRC site.

Clothing and Personal Protective Equipment (PPE)

Outdoor workers’ clothing should not be loose fitting, faded or torn. Council-approved garments for general outdoor workers are:

Outdoor workers’ clothing should not be loose fitting, faded or torn. Council-approved garments for general outdoor workers are:

- broad-brimmed hat

- steel-cap boots

- 100% cotton long sleeve high-vis shirt (with sleeves rolled down)

- 100% cotton long pants (recommended)

- gloves

Safety footwear (Steel Cap) must be worn on all TRC work sites by all employees, contractors and site visitors. Safety boots must comply with Australian Standard 2210.

Plant Equipment

The Act imposes health and safety obligations on designers, manufacturers, importers, suppliers, installers and erectors. Plant standards and operation must follow strict guidelines to ensure compliance with legislation.

The Act imposes health and safety obligations on designers, manufacturers, importers, suppliers, installers and erectors. Plant standards and operation must follow strict guidelines to ensure compliance with legislation.

Plant owners are responsible for:

- ensuring the work required of the plant is not beyond the safety capacity of the plant

- ensuring the plant, as delivered, is serviced and in good working order

- allowing the plant to be operated under the direction of the hirer (dry hire) and demonstrating the safety features

- ensuring the operator and additional personnel have certificates of competency to operate the plant (where applicable)

- ensuring plant equipment has a pre-start check done prior to its operation

- supplying details of the appropriate servicing and maintenance requirements of the plant

- ensuring appropriate operating manuals are provided with the plant.

Plant hirers are responsible for:

- checking the plant is in good condition when delivered and specifications are met under the hire contract

- ensuring appropriate operation manuals are delivered with the plant

- ensuring the operator has the appropriate certificates of competency (where applicable)

- ensuring a condition report (or maintenance record) is available for the supervisor of the plant.

First Response Fire Training

All fires start small and this is when you have the best chance of putting them out with a fire extinguisher.

First Aid Management

You need to:

You need to:

- know the identity of the first aid officer

- know the location of the nearest first aid kit

- ensure the first aid kit is sufficiently stocked and is within the used-by-date

- have a process in place.

Electrical Safety

The following requirements are to be adhered to:

- Electrical equipment must be tested and tagged and within date.

- Check the equipment for damage before use.

- Electrical equipment must be connected to an residual current device

- faulty electrical equipment is to be tagged ‘Out of Service’, removed and reported to your supervisor.

- Use intrinsically safe equipment where possible i.e. cordless drill.

- Double adaptors are not permitted.

Handling Sharps

For the safe removal of needles, syringes or other sharp objects:

- avoid putting your hands in hidden areas without checking first

- wear the appropriate personal protective gloves

- do not recap needles

- use tongs to pick up needles

- place needles in an approved sharps container

- dispose of gloves in the appropriate manner

- ensure workers’ immunisations are up to date.

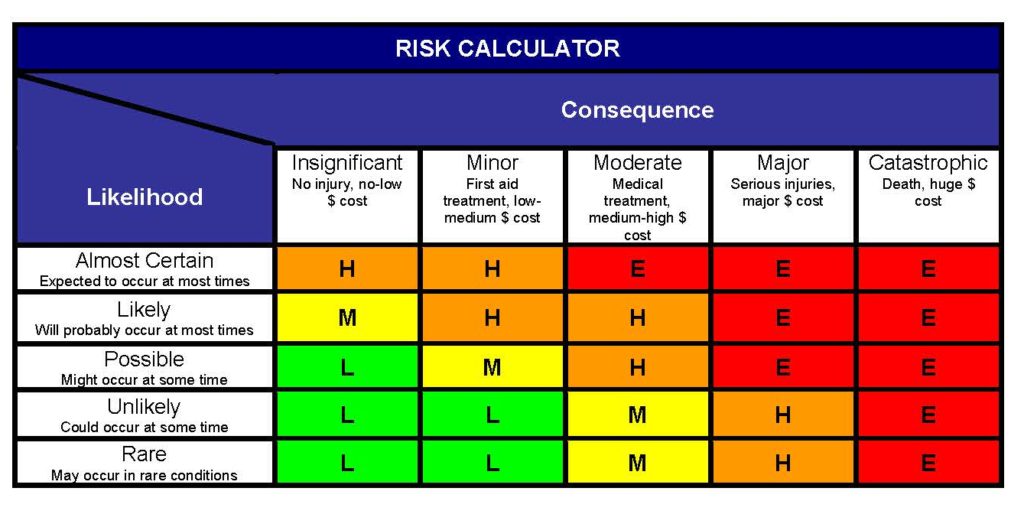

Risk Assessment

Hazard — a source or situation with the potential to cause harm.

Risk — the likelihood that harm will occur.

Risk calculator — helps rank the risk.

Ensure a written risk assessment and/or safe work method statement (see below) is conducted prior to work commencing.

Hazard Reporting

A hazard is something that has the potential to cause injury, damage or loss.

STOP

LOOK

ASSESS

MANAGE

Risks associated with hazards must be controlled and reduced to a low level and it’s everyone’s responsibility to report hazards.

Safe Work Method Statement (SWMS)

The primary purpose of a SWMS is to help supervisors, workers and any other people in the workplace to understand the requirements to carry out the high-risk construction work in a safe and healthy manner.

The aim of a SWMS is to:

- describe the activity or task to be undertaken

- identify the resources, personnel requirements and skills associated with the task

- assess hazards and risk level of tasks and select control measures (as appropriate)

- systematically plan the activity so it can be completed safely, efficiently and effectively.

The SWMS must be kept at the workplace where the high-risk construction work will be carried out. A PCBU that carries out high risk construction work must ensure a SWMS is prepared or has already been prepared before the proposed work commences.

High risk construction work includes work that:

- involves a risk of a person falling more than 2m

- is carried out on a telecommunication tower

- involves demolition of an element of a structure that is load-bearing or otherwise related to the physical integrity of the structure

- involves, or is likely to involve, the disturbance of asbestos

- involves structural alterations or repairs that require temporary support to prevent collapse

- is carried out in or near a confined space

- is carried out in or near a shaft or trench with an excavated depth greater than 1.5m

- a tunnel

- involves the use of explosives

- is carried out on or near pressurised gas distribution mains or piping

- is carried out on or near chemical, fuel or refrigerant lines

- is carried out on or near energised electrical installations or services

- is carried out in an area that may have a contaminated or flammable atmosphere

- involves tilt-up or precast concrete

- is carried out on, in or adjacent to a road, railway, shipping lane or other traffic corridor that is in use by traffic other than pedestrians

- is carried out in an area at a workplace where there is any movement of powered mobile plant

- is carried out in an area in which there are artificial extremes of temperature

- is carried out in or near water or other liquid that involves a risk of drowning

- involves diving work.

Lifting and Manual Handling

Manual handling is involved in nearly all work in our industry. Plan your work, rotate and/or vary your tasks to reduce repetitive strain injuries.

Manual handling is involved in nearly all work in our industry. Plan your work, rotate and/or vary your tasks to reduce repetitive strain injuries.

Manual handling injuries are commonly sustained through:

- incorrect lifting or handling practices

- poor postures or technique

- repetitive work

- vibration.

Before lifting, ask yourself if you should be using mechanical lifting aids.

Noise Management

A worker who is exposed to a high level of noise, above 85 dB(A) as part of normal work, must wear appropriate hearing protection. Hearing protection must also be worn when a mandatory sign indicates it is required and/or you are working with noisy tools, plant or equipment.

A worker who is exposed to a high level of noise, above 85 dB(A) as part of normal work, must wear appropriate hearing protection. Hearing protection must also be worn when a mandatory sign indicates it is required and/or you are working with noisy tools, plant or equipment.

Housekeeping

The tidier your workplace, the safer it will be. Good housekeeping will prevent slips, trips and falls. If you come across a hazard, clean it up

provided you are trained and it is safe to do so.

Lone or Remote/Isolated Work

Workers must be contactable, and their location and start and completion times known.

Signs

Chain of Responsibility (CoR) — National Heavy Vehicle Regulator (NHVR)

Multiple parties may be responsible for offences committed in heavy vehicle operations. A person may be a party in the supply chain in more than one way and legal liability can apply to their actions, inactions and demands.

A heavy vehicle is one that has a gross vehicle mass (GVM) over 4.5t (i.e. the maximum mass stated by the manufacturer the vehicle can have when it’s loaded).

Like any other party in the transport supply chain, contractors are responsible for preventing breaches of mass, dimension, loading, fatigue, speed and vehicle standards (maintenance) laws. If you manage vehicles that come under the National Heavy Vehicle Law, you need to understand the legal requirements of:

- monitoring drivers’ health and fitness for duty

- scheduling their work and rest hours

- keeping records of the hours they work.

Smoking

Smoking is prohibited in TRC offices, depots, vehicles, plant and workplaces for all workers and contractors. Smoking is only permitted in normal work breaks in designated smoking areas.

Smoking is prohibited in TRC offices, depots, vehicles, plant and workplaces for all workers and contractors. Smoking is only permitted in normal work breaks in designated smoking areas.

Silica

Continual exposure to and breathing in of dust containing silica particles can cause lung disease. To avoid or minimise the exposure to silica dust”

- wet the immediate area to keep the dust down

- wear appropriate PPE, including a properly-fitted dust mask or respirator.

Workplace Chemicals — Safety Data Sheets (SDS)

SDSs provide relevant information on:

SDSs provide relevant information on:

- the chemical compound

- associated health hazards

- safe handling practices

- how to use the chemical safely

- emergency and first aid

SDSs must be kept close to the storage area for each chemical and a copy taken and carried with mobile plant and vehicles that carry chemicals.

Asbestos

You must be fully trained and certified to work with asbestos and:

- must have a copy of the Asbestos Management Plan before proceeding

- must not drill, cut, sand or grind asbestos

- if cutting is unavoidable, lessen the dust by wetting down the material

- must use the appropriate respiratory protection and other PPE

- must dispose of asbestos.

If you come across pipe insulation, lagging, ceiling insulation or other fibrous material suspected of containing asbestos, notify the relevant Council officer or a WHSA before continuing the work.

Incidents & Near Misses

You must immediately report all incidents, near misses and injuries (no matter how minor) to the site foreman, relevant Council Officer or WHSA.

Instrument of Appointment

The basic steps in contractor management are:

- Contract specification — determine WHS tender and contract requirements

- Tender evaluation — evaluate tender WHS capabilities and systems

- Contract management — monitor and supervise contractor WHS performance.

Engaging Minor Contractors

The Instrument of Appointment for Engaging Vendors/Minor Contractors Subcontractors is to be used when a contractor carries out specific tasks (e.g. maintenance work, minor repairs, testing and tagging of electrical equipment etc). This is to be reviewed yearly for all minor contractors.

Every worker and owner needs to fill out this Instrument of Appointment form below, and complete the contractor induction assessment.

Instrument of Appointment for Engagement

"*" indicates required fields

Contractor Induction Assessment

"*" indicates required fields